This work will not deal with fifth and sixth order deviations related to the structure of the material, mechanisms of physicochemical bonding of the surface or particle size. Deviations are extensively studied in international standards (DIN4760). The surface finish is determined by the magnitude of the deviations measured from a nominal surface. With this condition, it is possible to determine the quality and functionality of an element. Surface roughness is mostly a requirement on any product / process design. Additionally, machine tool mismatches also include defects on machined surfaces. Several authors make representations of the roughness from the idealization of the geometric patterns that are generated by the effect of the trajectory of the cutting tool, however, the hardness of the material, its grain size and the thermal or acoustic effects during cutting prevent the formation of stable geometric shapes. To understand the surface roughness, it is necessary to simplify the problem and avoid the rheology of the workpiece material to omit thermal phenomena, wear or vibrations that can affect the ideal path of the edges of the tool. Palabras clave: rugosidad, dirigir, inclinación, avance transversal, diseño de experimentos, simulación, ISV. Las desviaciones de cuarto orden están asociadas al avance por diente, con una velocidad angular constante de 5.000 rpm. El ángulo lead tiene una influencia moderada. Como resultado, se obtiene un valor óptimo (mínimo) de rugosidad. En el experimento se presenta un modelo factorial 3 k para precisar el factor de mayor influencia sobre la rugosidad. Se realiza un diseño de experimentos para determinar la influencia de los factores geométricos dinámicos: avance transversal (Ae), ángulo lead y ángulo tilt, con herramienta de fresado de punta plana de diámetro 1 mm.

Cnc simulator tilt software#

El entorno de simulación es desarrollado a partir de la integración y verificación simulada (ISV) en software NX 11 y las aproximaciones geométricas son validadas por medio de microscopia confocal. Por medio de modelos experimentales, geométricos y simulaciones, se determinan valores de rugosidad propia de desviaciones de tercer y cuarto orden. Keywords: roughness, lead, tilt, transverse feed, design of experiments, simulation, ISV.

Fourth order deviations are associated with the feed per tooth, with a constant angular speed of 5,000 rpm. As a result, an optimum (minimum) roughness value is obtained. In the experiment a 3 k factorial model is presented to specify the factor with the greatest influence on the roughness.

Cnc simulator tilt verification#

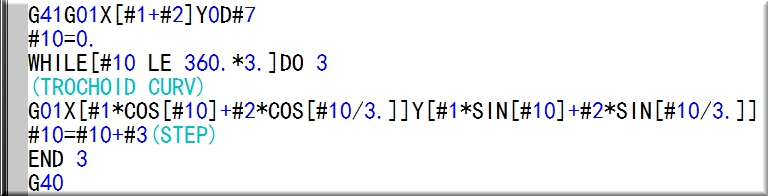

The simulation environment is developed from the integration and simulated verification (ISV) in software NX 11 and the geometric approximations are validated through the analysis confocal microscopy.Īn experiment design is carried out to determine the influence of the dynamic geometric factors: transverse feed (Ae), lead angle and tilt angle, with a flat end milling tool with 1 mm diameter.

By means of experimental, geometric and simulation models, roughness values of third and fourth order deviations are determined.

0 kommentar(er)

0 kommentar(er)